What is Kanban Methodology & its Best Practices? (With Definition)

Everyone knows the value of Kanban in terms of product management, so we added our take on the well-known Kanban methodology.

What Is Kanban Methodology?

Kanban Methodology Definition:

Kanban methodology is a software development process within the agile framework that focuses on limiting the amount of work-in-progress (WIP) at any given time.

The meaning of kanban in the literal sense is ‘sign.’

Its purpose is to ensure a smooth iterative (agile) workflow pipeline. It also helps to limit the number of backlogs that may arise due to excessive pressure on the channel or other issues you need to identify and resolve quickly.

You can apply the basic disciplinary concepts that make Kanban a successful work management formula in software and other fields.

Where Did Kanban Originate?

The first Kanban system was developed by an industrial engineer and businessman Taiichi Ohno for Toyota automotive in Japan during the 1940s.

Kanban was a simple planning system to optimally control and manage work and inventory at every production stage.

One of the main reasons for the kanban development was Toyota’s inadequate productivity and efficiency compared to its American counterparts at the time.

Now, the term Kanban itself, pronounced “Kahn-Bahn,” is a Japanese word that means visual signal or card. The Kanban system works on “Visual Management” and limits work-in-processes to avoid bottlenecks.

The goal of applying this methodology is to reduce cost, and increase productivity and quality, while simultaneously improving delivery time.

Unlike other workflow management methods, Kanban is about evolution, not revolution. It rests on the fundamental truth that you must know where you are before getting to your desired destination.

The beauty of this method is that you can apply a Kanban to virtually any type of work that follows a repeatable process.

During its founding all those years ago, Toyota line-workers used a Kanban (at the time, an actual card) to signal steps in their manufacturing process.

In its original iteration, before the accessibility of technology, Kanban were physical boards with manually updated cards.

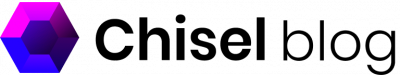

Now, product management software like Chisel lets you do the same activity synchronously with your team online.

Initially, the Kanban system controlled the entire value chain from the supplier to the end consumer. It helped avoid supply disruption and overstocking of goods at various stages of the manufacturing process.

In 2004, David J. Anderson applied the concept to IT, software development, and knowledge work in general.

A Brief History of Kanban Methodology for Software Development

Let’s look at the following exurb. It is from David J. Anderson’s blog post titled “A History of Kanban for Creative Knowledge Work.”

October 2004

Dragos Dumitriu asks David J. Anderson, manager of XIT sustaining engineering at Microsoft, for help. David created a pull system for Dragos’ group and coached him on how to introduce it. Dragos then sold the idea to his bosses and his four product managers.

Microsoft product studio implemented the system with no physical board, and the engineering team was in Hyderabad, India.

The method implemented was inspired by the Theory of Constraints Drum-Buffer-Rope and worked on assuming that the test was the bottleneck.

2005

Winter of ’05: Donald Reinersten watched a presentation of David’s flow and FDD material at a conference in Chicago and followed him home to Seattle. Donald visited him in the café of Building 25 on the Microsoft campus and persuaded David to try Kanban systems.

David decides to revisit the XIT implementation as a Kanban system. He discovers that little would change; perhaps the WIP limits would be slightly different.

David finds Kanban systems easier to explain to people and starts referring to XIT implementation as a virtual Kanban system and presents it the following year in Chicago.

In October of 2005, XIT sustaining engineering study was presented at TOCICO in Barcelona and published as a white paper by Microsoft.

2006

Winter of ’06: David presents the completed XIT story as a virtual kanban system implementation at the same Chicago conference Donald followed him home from the previous year.

It is the first public presentation of Kanban systems used in a knowledge work setting. Previously, only Dragos and David were involved.

Summer of ’06: Some people read and implement copies of the Microsoft IT solution. Notably, Eric Landes from Robert Bosch copied it almost precisely for use with an intranet website maintenance team.

September of ’06: David changes jobs to become Senior Director of Software Engineering for Corbis.

He realizes the software maintenance process is badly broken and works with Rick Garber, the manager of the process improvement team, to design a Kanban system.

It was to replace the existing project-centric approach to minor application upgrades.

When working with stakeholders, Drew McLean, a VP at Corbis, suggests the expedite capability, which added the first alternative class of service to a Kanban system for knowledge work.

Darren Davis, development manager for maintenance, and Diana Kolomiyets, the project manager, took control of the Kanban implementation in November 2006.

Darren takes charge of standup meetings, and Diana runs the replenishment meetings every week and plans and coordinates releases every two weeks.

December of ’06: There is an operations review of IT at Corbis. Darren Davis presents results from the first Kanban system implementation during an assessment.

2007

January of ’07: Darren Davis suggests that due to stagnation of improvements after a series of successful releases from the maintenance process, there appears to be so much variation inflow. No one knows what to do next.

He suggests visualizing the workflow using a card wall implemented on a whiteboard across the hallway from his cubicle. This idea was from one of his team members. A board goes up on the wall.

Winter of ’07: The wall is helping with further improvements, and capacity is set aside for internal demand. A WIP limit of 2 is there for green tickets.

David noticed a trend for urgent work with externally fixed dates. He suggests offering a “fixed date” concept as a class of service.

What is now known as the Kanban method, with its six practices and risks visualized and addressed using capacity allocation and classes of service, emerges at the end of this season.

Corey Ladas is hired away from Microsoft to be a process coach for Kanban at Corbis.

April of ’07: The incoming CEO of Corbis asks why if the new maintenance process is working so well, then why isn’t it being used across all of IT. David agrees and rolls out Kanban across the project portfolio.

The digital asset management (DAM) project adopted Scrum and Kanban under Corey’s guidance. It is the first instance of a two-tiered Kanban board with swim lanes.

May of ’07: Dan arrives as the development manager for the ERP project. Dan’s never worked with Kanban, but he and Corey design the process for the project.

They roll the staff from the DAM project onto the ERP project bringing along the two-tiered, swim lane Kanban board.

June of ’07: Donald holds a Lean New Product Development conference in Chicago, and Rick Garber and David present. There were only 55 people in the audience.

It is the first presentation of what is now known as the Kanban method, complete with classes of service, lead time histogram metrics, operations review, and so on.

August of ’07: David presents the same presentation from June at the conference within a conference at the Agile Conference in Washington D.C.

Members from Yahoo! are in attendance (Karl Scotland, Joe Arnold, and Aaron Sanders) and approach David the next day.

They tell David that his evolutionary approach to change and alternative path to agility using virtual Kanban systems appeal to them.

They explain that they have tried to implement Scrum at Yahoo! and that there is much resistance. They want to try Kanban with the resisting groups.

They set up a Yahoo! discussion group to share their experiences. The kanbandev group was born today and is still in use at Yahoo!

2008

August of ’08: Corey Ladas presents more detailed implementation scenarios at the Agile 2008 conference. Half of the presentation focuses on Kanban applied to teams and projects using Scrum. It is the foundation of what would be known as scrumban.

2009

January of ’09: Corey Ladas’ book Scrumban is published based on a series of blog posts about evolving Scrum using Kanban.

May of ’09: The first Lean Kanban conference is held in Miami, an idea proposed by the kanbandev group at Yahoo!

David meets with Jim Benson to reflect on the conference in Miami.

They discuss how Kanban for personal use is different from corporate workflow usage (now known as the Service Delivery Kanban).

There’d been an instance of personal usage emerging worldwide, including the Modus Cooperandi office.

July of ’09: Jim Benson launches Personal Kanban as a series of 12 blog posts.

October of ’09: Jim Benson launches personalkanban.com.

2010

Kanban– Successful Evolutionary Change for your Technology Business is published.

It has become the best and most complete reference for implementing Kanban systems in creative and knowledge-worker businesses. It has sold well over 40,000 copies.

What Are the Key Kanban Methodology Principles?

The five fundamental principles that make the Kanban methodology an effective development process are:

Agreement on incremental agile framework

Kanban can only take effect within an agile working framework. The product will be developed in iterative cycles, building on the previous version. It is fundamental to the Kanban methodology.

It, of course, is based on the fact that user preferences and market landscapes change too fast not to be taken into account while developing a new product or feature.

Each iteration, therefore, is set in only weeks, not months or years, when the product may be already outdated or lacking key customer preferences.

Starting with what is certain while leaving room for uncertainty

Teams that choose Kanban start by acknowledging that they may not know or understand every user’s needs right at the beginning.

The product will need to be delivered in versions – starting with what they know and building towards betterment based on new insights.

Furthermore, starting with the primary product model that passes the economic cost-benefit analysis and feasibility tests prevents delays from excessive planning and decision paralysis.

Limit work-in-progress (WIP)

Kanban aims to limit the total work-in-progress at any given time.

It is done through pressure tests on the bandwidth through managerial guidance and carefully noting the capacity of each team and member.

Once a reasonable estimate of work can smoothly pass through the development and test cycles into production, teams should manage the workflow accordingly in each sprint/ build cycle.

It is not to say that there should be no increase in the workflow as the team matures and gets more accustomed to the product’s development and processes. The pressure tests should take place from time to time.

Companies need to plan additional resources based on the work that teams need to do to meet business goals and the team’s capacity to deliver.

Iterations based on user feedback

Since Kanban aims to deliver the product in versions, user feedback is a vital insight source that determines the work.

User-need surveys and experience studies are a cornerstone in the Kanban methodology of development since the point of delivering a product under continuous growth is to stay informed on user preferences and provide it before competitors.

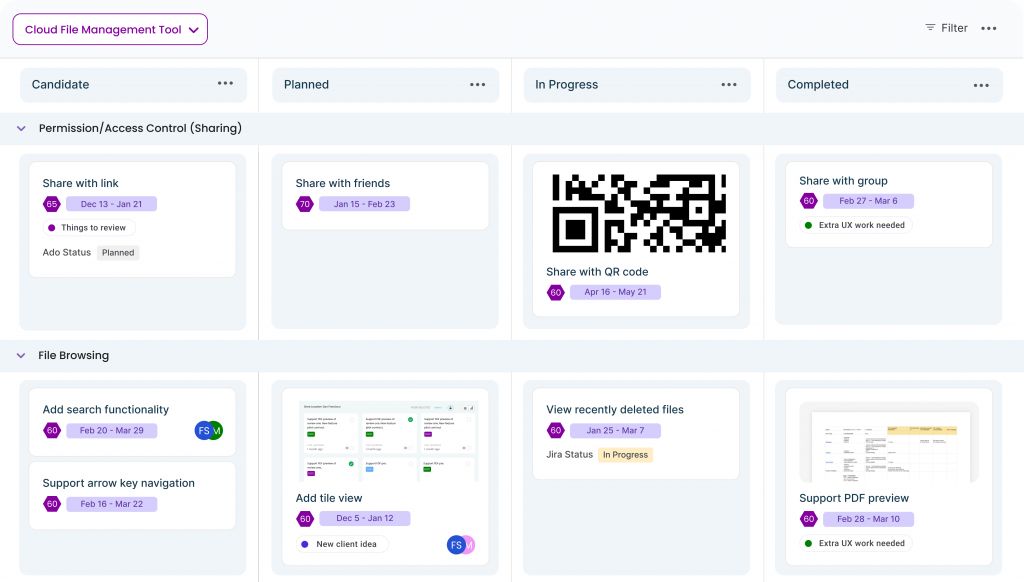

Teams should scan user feedback and feature requests through a cost-benefit lens, and prioritizing the feature development is done accordingly.

Delivery ownership and team alignment over documentation

One of the fundamental principles that allow for fast development is to create an environment of trust and ownership of final work delivery, even if no one is checking in.

Task management from managers is still crucial with pipeline management and code documentation. However, comments and spreadsheets have been reduced for better team alignment and self-accountability.

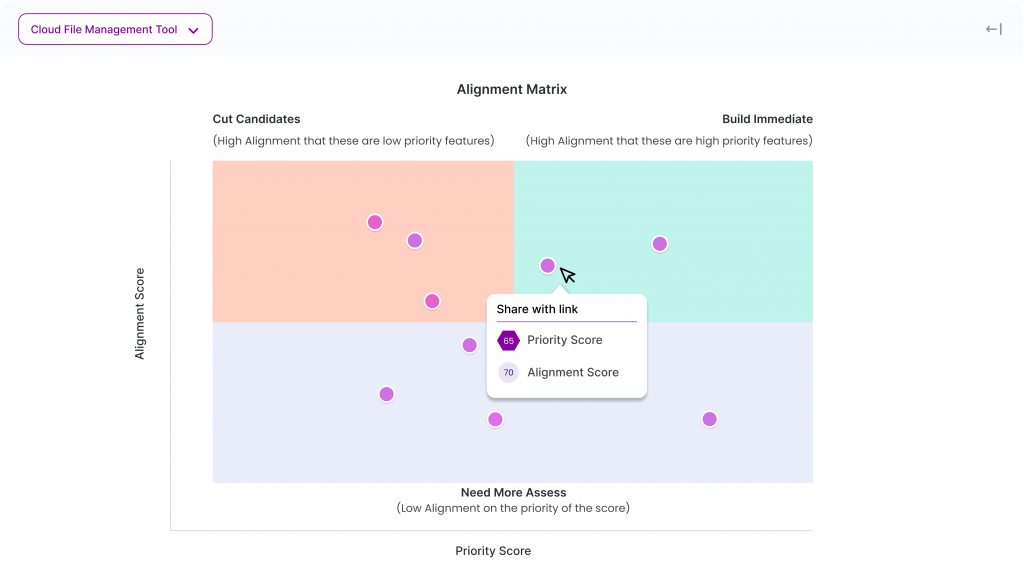

Kanban Methodology Development Model: Life-Cycle Stages

Based on the principles of Kanban methodology, below are the iterative stages within the method:

Stage 1. Product feasibility test and early need-analysis

Product-need analysis is undertaking prospective-user surveying and understanding of the demand for such a product, gaps in current products (if any), and the key features essential to break into the market.

Based on this initial must-have list of features, teams must do a cost-benefit analysis to understand the short-term and long-term potential return on investment.

Once this stage is precise, teams can conceive any product development.

Stage 2. Team alignment

Team alignment is critical for any agile framework, including Kanban.

Before starting any actual development work, it is critical to pull your team together for one or several alignment sessions to chalk out clarity on every feature, method, and process.

Team alignment is key to a smooth functioning work pipeline and timely delivery with minor bottlenecks, given work ownership and cross-team collaboration, especially in remote working post-covid lockdowns.

Stage 3. Product definition

“Creating product vision, feature roadmap, and prioritization” – Product managers create a product and feature roadmap that is both compelling and achievable.

They use their in-depth understanding of the target customer’s needs, the engineering team’s capabilities, and available technologies. Using this understanding, they create a product backlog to ship the right features at the right time.

Stage 4. Product development based on existing clarity

Once your team is aligned, it is time to move forward with your first iteration’s development work. This stage ends with the development of the planned iteration until it gets sent for QA and testing.

Stage 5. User-experience and QA tests

Internal quality assurance (QA) tests are the first layer of error-free product production. QA engineers only test the product or feature based on how the initial intentions were to function as per the build plan.

If the product clears QA, the final test on end-user experience is conducted by a panel of users to identify gaps in navigation, layout, user-interface friendliness, intuitiveness, and so on.

Stage 6. Modifications and Production

If the user-feedback test returns with sanctioned pre-production updates, teams must implement these last-minute changes.

Also, the QA must verify it, and teams do no further user tests. Once the product passes QA, it goes into production.

Stage 7. Repeat

Once the product hits the market, the product manager needs to go back to step 1 to plan the next iteration.

The 6 Rules Of Kanban Methodology

Never Push Through A Defective Product

There is a level of quality expected when creating a product. You ought to remove any defective features and deal with them. It ensures only the highest quality product gets to your customer.

Because of the above reason, in software development, every application has to go through rigorous quality assurance testing before anything is released. Only once the product has passed testing, then, and only then, can a product be released to the market.

Focus only on what’s needed

Avoid getting bogged down in customer requests or orders on your product. You don’t want to incorporate every feature request because you’ll be at risk of becoming a feature factory.

Your backlog has prioritization; follow it.

Produce what is required

It goes hand in hand with focusing only on what’s needed.

Having a minimum viable product mindset is imperative when creating a new product.

You need your product to functionally work in the way the customer is working for, nothing more, nothing less.

The absolute minimum requirements are what you ought to focus on creating and then building your product out as the market demands moving forward.

Don’t overwork your developers.

One of the more ingenious aspects of Kanban is setting your work-in-progress limit based on your limiting contributor.

The WIP exists so that when you spot a bottleneck, you can alleviate the burden by redirecting your resources and setting a WIP to prevent any long-term issues.

Fine-tune and optimize the processes

Kanban metrics like lead time, cycle time, and throughput will help teams get quantitative and objective work assessments.

Teams must be looking for activities that produce excess bloat and eliminate them.

Regular team meetings where everyone discusses experiences, pain points, and improvement suggestions are key in fine-tuning production as inefficiencies decrease. WIP items are also lower because the process is lean.

Finalize the process

When you ensure quality and fair production and optimize your process, your process becomes stable and finalized.

You should document your process, so there is a common understanding of how everything should operate.

Other policies should manage any deviation from the process.

Keep in mind, though, that everything can evolve through time as you fine-tune your process.

More like this:

- What is Kanban Card?

- 11 Best Product Planning Software

- How to Prioritize Product Roadmap With Matrix?

- 9 Best Kanban Board Software

- What Is the Agile Manifesto

- How to Use a Scrum Master

- Top 9 Scrum Master Certifications and Their Value

- Most Popular Agile Certifications To Consider

- Do You Use Agile or Waterfall Development